T-2C Buckeye

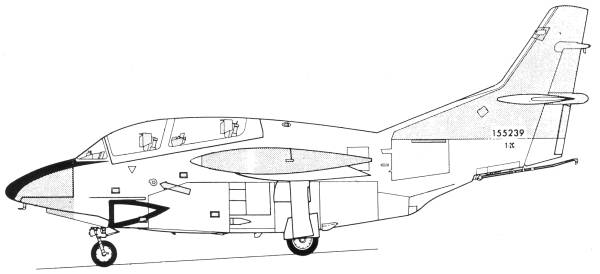

In 1956 the U.S.Navy introduced a requirement for a new jet trainer to replace the T-28 Trojan. North American Aviation emerged as the winner and immediately produced six YT2J-1 aircraft. These were actually pre-production aircraft and North American skipped the entire prototype phase. The first flight for the Buckeye was January 31, 1958. All aircraft were produced in Plant 85 just south of Port Columbus Airport in Columbus, Ohio. As purpose build trainer, the Buckeye had many design features that were beneficial to student aviators. A wide tricycle landing gear, powered controls, large trailing edge flaps, speed brakes and a robust tail hook. he instructor pilot also sat in an elevated back seat to facilitate a good view both inside and outside the cockpit.

The Buckeye was produced in three main variants.

The T-2A was powered by a single 3400 pound thrust Westinghouse J34-WE-48 fuselage mounted turbojet as were the initial production models. 201 of this version was built entering service in July of 1959.

The T-2B entered service in 1962 and was essentially an upgraded T-2A. The single turbojet was replaced with two 3000 pound thrust Pratt and Whitney J60-P-6 turbojets. This conversion was chosen to replace the T-2A and the first of the 97 new aircraft flew on May 21, 1965 and entered service in December of 1965.

The T-2C was a T-2B converted for evaluation with two General Electric J85-GE-4 turbojets. This lead to the production of 231 with the first production model being flown on December 10, 1968.

The Buckeye trainer was used to train over 11,000 student pilots and established an outstanding record of safety and reliability for many years. Virtually every naval aviator from the late 1950's to 2004 received their pilot training in this aircraft. The last pilots to complete their carrier qualifications did so on July 17, 2003.

The Kit

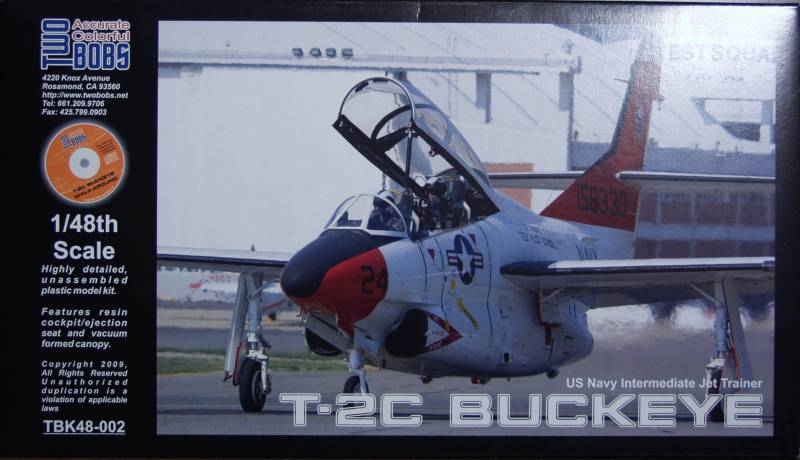

Two Bobs as a brand name was known prior to the release of this kit as a designer and makers of after market decals. Although the kit number would indicate it was the second kit released I believe it was the only one that was produced under their name. The kit is a limited run style kit that was molded for Two Bobs by one of the Eastern European makers and looking at the parts you will see a lot of similarities between it and other short run kits from the likes of Special Hobby. Special Hobby also released this kit under their name. That said, lets look and see what we get.

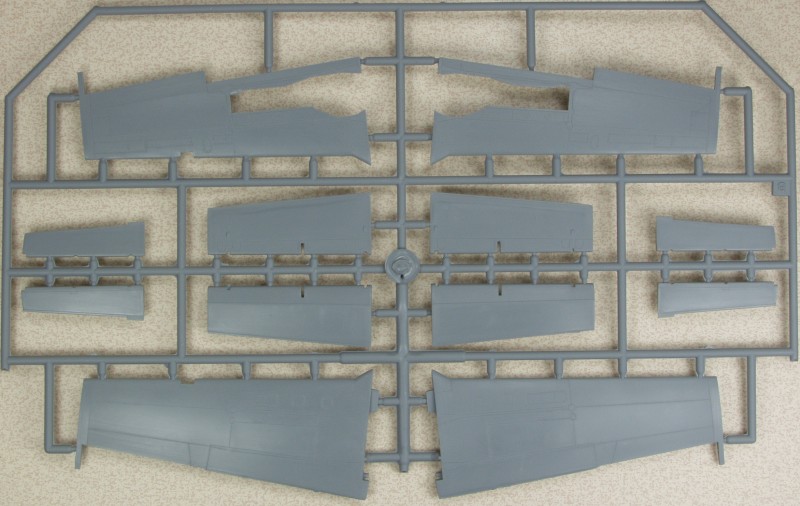

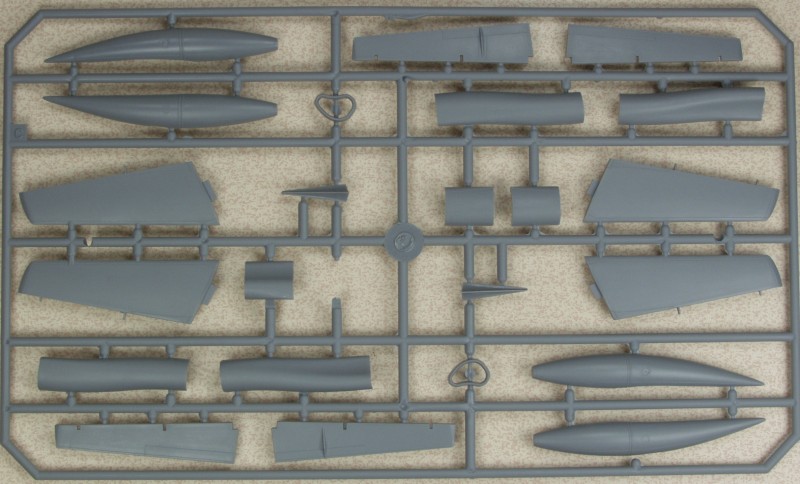

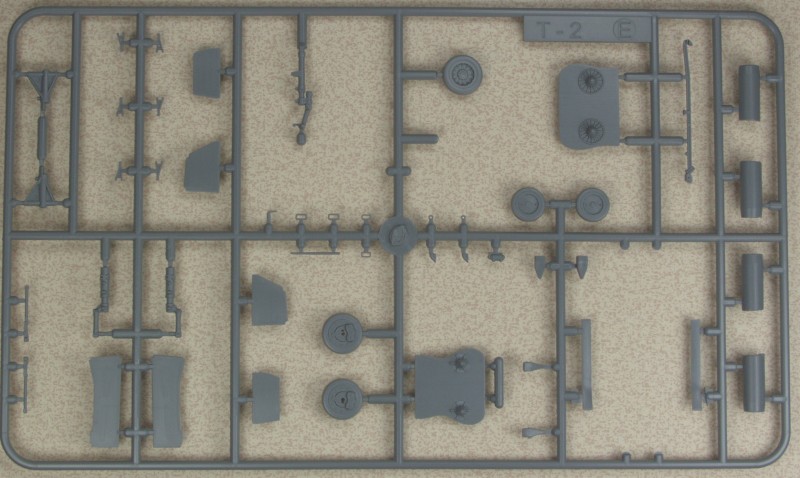

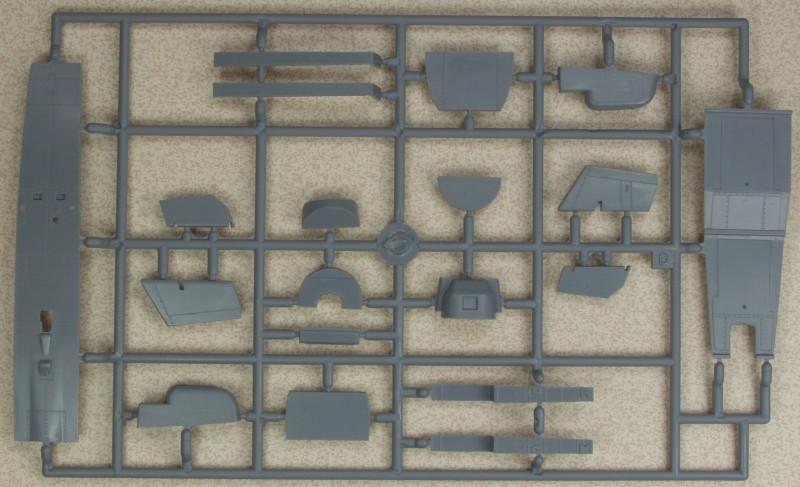

The kit comes in a top open tray type box with the bottom half made from thin corrugated cardboard to provide a sturdy box. The box has a nice photo of the prototype on the top. Inside the box all of the parts with the exception of the resin parts and clear parts are all in one resealable bag. The resin parts are in a zip lock bag and the clear parts in another resealable bag. The main kit parts are molded in a dark gray color an have the look and finish of most short run, low pressure molded kits. That said the surface detail is quite nice with very fine engraved detail including panel lines, rivets and fasteners. Much of this is fine enough that it will be easily lost to too many or heavy coats of paint. There is also some raised detail where applicable. Inside the fuselage you will find some raised ejection towers, some of which may need to be trimmed down for fit purposes. There is some flash evident but what is there should be easily dealt with. All of the flight control surfaces are separate including the flaps. I did not spot any surface defects on my kit but like many limited run kits the sprue attachment point are heavy in places and will need care when removing. Mold alignment appeared to be good so clean up of mold separation lines should be easy.

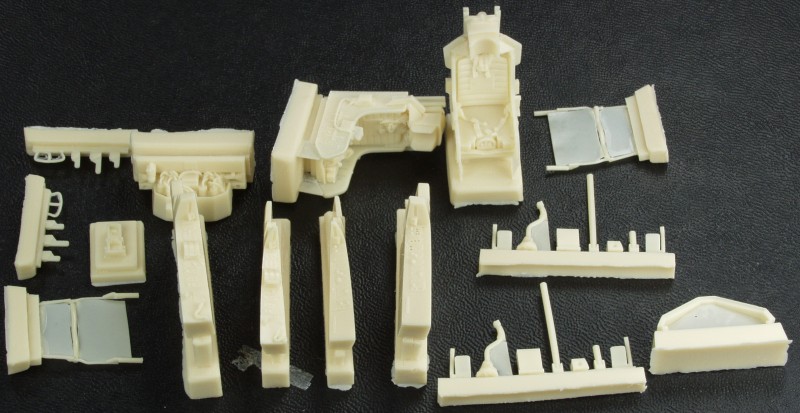

From a detail standpoint the cockpit is quite nice. The instrument panels are plastic as is the front cockpit instrument console. The rear seat console is resin. The instrument panels feature raised instrument with internal dial detail but this is quite shallow and looks like it would be hard to paint. The cockpit floor and structural dividers are plastic while the side consoles, rudder pedals, joysticks, seats and other details are done in resin. It should make for an attractive cockpit. No engines are supplied, just intake and exhaust turbine faces. Intake and exhaust ducts are supplied but these are in halves so dealing with seams can be problematic. The wheel wells are boxed in and have structural detail. The front external intakes are mad up from three pieces and feedback from builders indicates the fit here is not good so plan on taking your time here and do a lot of test fitting. The landing gear are nicely done but the main gear inside door actuator struts look positively delicate so care will be required with these. The canopy can be posed open or close with an appropriate actuator strut. Lets look at the parts.

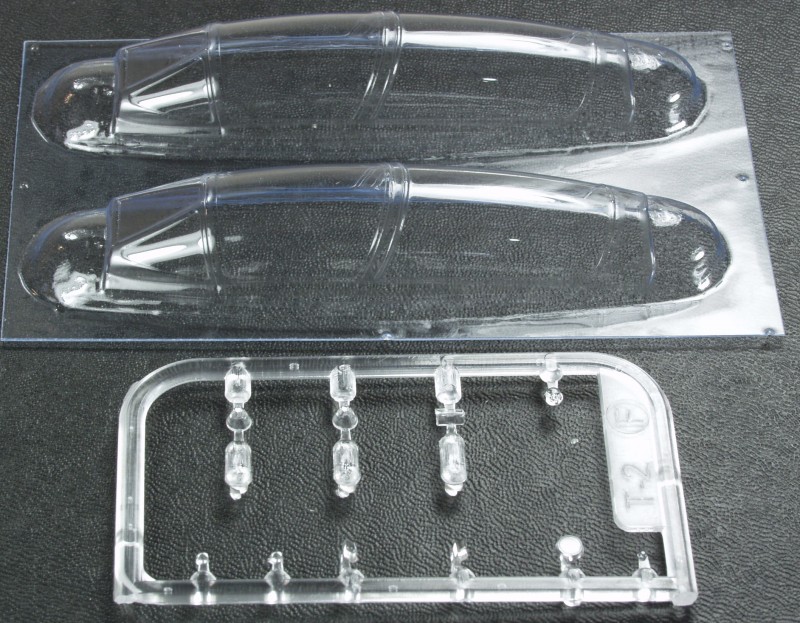

The clear parts are provided a vacuform parts. These look nice with minimal distortion and are made with a thicker plastic than is commonly seen of canopies. The front windshield is not as clear as the rest of the canopy but a dip in Future should improve it. Two are supplied in case of disasters. The rest of the clear parts, landing and navigation light lenses are injection molded.

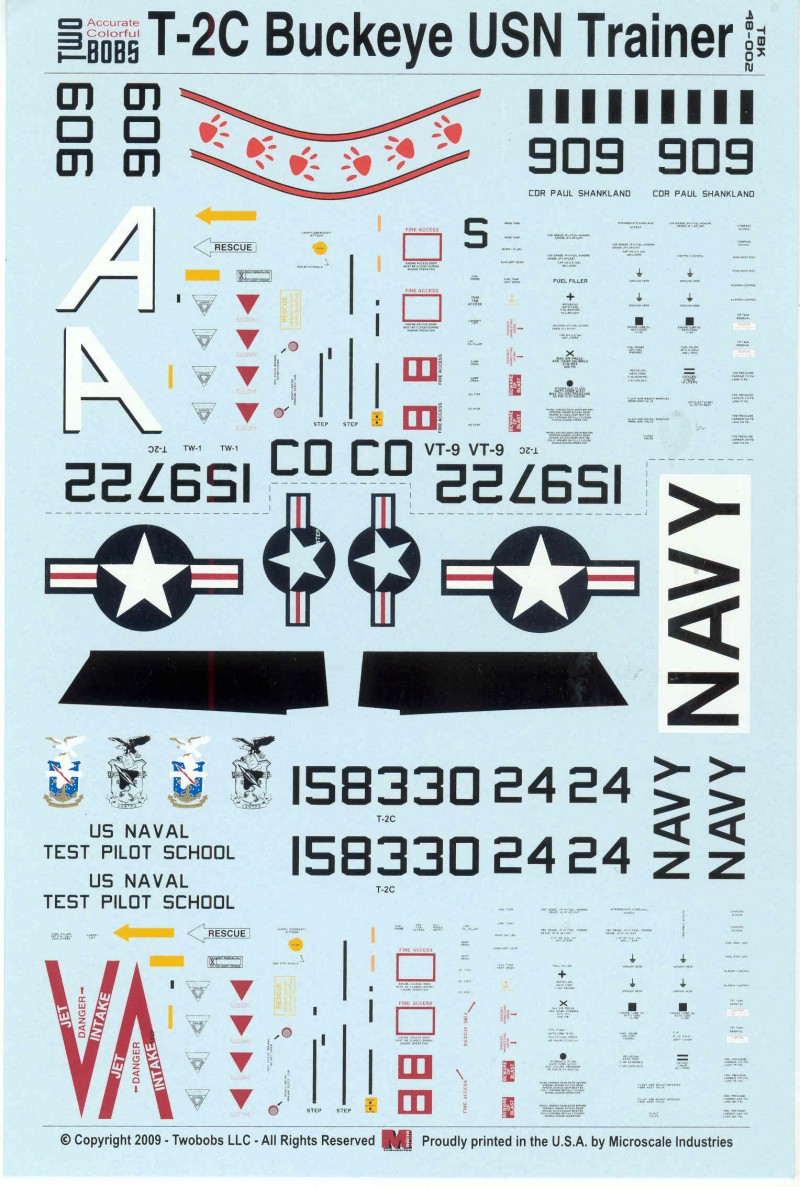

The decals are printed by Microscale so they should be excellent and since Two Bobs specialty is accurate well done decals these look the part. Decals for two aircraft are supplied, one from NAS Meridian, sept 2003 and the other from NAS Patuxent River, May 2006. The sheet looks excellent and there are enough stencil decals to keep one busy for a long time.

The instructions are a small booklet style made from two pages printed on both sides and folded. The first page has history an specifications, the second page a parts map which is handy as the sprues are not numbered. The balance is assembly steps, 31 in all. Some of the pages are quite busy but still reasonably clear. Also included is a glossy color page printed on both sides with the painting and decal information. Included in the Two Bobs kit is a CD with over 300 high resolution walk around images of the T-2C.

After Market Goodies

Slim pickings here, I only found some replacement metal landing gear from SAC and they don't offer any extra detail unless you are concerned about the nose gear supporting the weight necessary to keep it from tail sitting.

Conclusions

For a limited run kit this one has some really nice surface detail an a lot of nice resin for the cockpit, you need to balance that with the fact that it is and needs to be treated like a limit run kit, lots of test fitting and expect to need to deal with parts that just don't fit well, especially in the intake area. Recommended for more experienced modelers with limit run kit experience.

Links to kit build or reviews

In box reviews here , here, and here.

References

Back to

the Misc 1/48 US page