P-47D

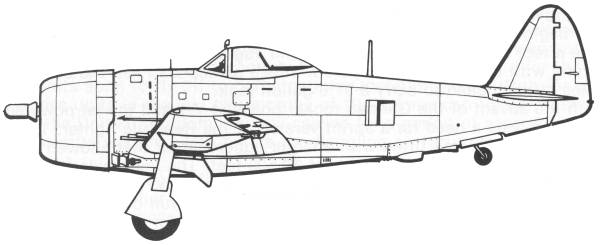

The P-47 was the culmination of a line of radial engined fighters that started with the Seversky P-35 which was produced in 1937 and 1938. While the P-35 was hardly a world beater it did give Seversky experience and a foot in the door when it came to fighter aircraft. Next in the line came the P-43 Lancer. About this time Seversky ran into financial problems and reorganized as Republic Aviation. While still not a world class fighter the Lancer did keep Republic's lines operating until a fighter design that would bring the US up to snuff with the rest of the combatants. That design was the P-47. The P-47 was designed around the most powerful engine available at the time, the Pratt and Whitney R2800. Republic knew that in order to meet the performance and load carrying demands being made by the Army Air Corps that the R2800 would require an efficient supercharging duct system and set about the unorthodox method of designing the system first and building the fuselage around it. A conventional three bladed propeller could not efficiently utilize the power of the new engine so a four bladed prop was adapted. This created a ground clearance problem and a longer undercarriage would have taken up room needed for guns and ammunition that was required so Republic designed a telescoping landing gear that was nine inches shorter retracted than it was when extended.

The first prototype, the XP-47B made its first flight on May 6, 1941. Even though it was twice the weight of most of its contemporaries, its 2000 hp engine still gave it a top speed of 412 mph. It was hoped that the design would be combat ready by May of 1942 but this proved optimistic as there were numerous teething problems and production did not begin until the Spring of 1942. the production P-47B differed from the prototype only in having a sliding canopy instead of a hinged canopy and a production version of the R-2800 and though its weight had increased the maximum level speed increased to 429 mph. One hundred and seventy-one B models were built.

The next production variant, the P-47C was similar to the B-model. Overall length increased, most of it due to an extension of the fuselage at the firewall. The rudder and elevator balance system was redesigned and the most important change was the addition of shackles to carry a 166 gallon ventral tank. Early C-models used the same engine as the B but later but later models used the R-2800-59 which was equipped with water injection which provided a War Emergency Rating of 2300 hp. The C-model was the first to see combat and 565 were built.

Refinements of the Thunderbolt continued, leading to the P-47D, which was the most produced version with 12,558 built. The "D" model actually consisted of a series of evolving production blocks, the last of which were visibly different from the first.

The first P-47Ds were actually the same as P-47Cs. Republic could not produce Thunderbolts fast enough at its Farmingdale plant on Long Island, so a new plant was built at Evansville, Indiana. The Evansville plant first built a total of 110 P-47D-1-RAs, which were completely identical to P-47C-2s. Farmingdale aircraft were identified by the -RE suffix after the block number, while Evansville aircraft were given the -RA suffix.

The P-47D-1 through P-47D-6, the P-47D-10, and the P-47D-11 successively incorporated changes such as the addition of more engine cooling flaps around the back of the cowl to reduce the engine overheating problems that had been seen in the field. Engines and engine subsystems saw refinement, (the P-47D-10 introduced the R-2800-63, replacing the R-2800-21 seen in previous P-47s) as did the fuel, oil and hydraulic systems. Additional armor protection was also added for the pilot.

The P-47D-15 was produced in response to requests by combat units for increased range. "Wet" (equipped with fuel plumbing) underling pylons were introduced to allow a bomb or drop tank pressurized by vented exhaust air to be carried under each wing, in addition to the belly tank.

The P-47D-16, D-20, D-22 and D-23 were similar to the P-47D-15 with minor improvements in the fuel system, engine subsystems, (the P-47D-20 introduced the R-2800-59 engine) a jettison able canopy, and a bulletproof windshield. Beginning with the block 22 aircraft, the original narrow-chorded Curtiss propeller was replaced by propellers with larger blades.

All the P-47s produced to this point had a "razorback" canopy configuration with a tall fuselage spine behind the pilot, which resulted in poor visibility to the rear. The first P-47 with a bubble canopy was a modified P-47D-5 completed in the summer of 1943 and redesignated XP-47K. Another older P-47D was modified to provide an internal fuel capacity of 370 U.S. gal (1,402 l) and given the designationXP-47L. The bubble canopy and increased fuel capacity were then rolled into production together, resulting in the block 25 P-47D (rather than a new variant designation). First deliveries of the P-47D-25 to combat groups began in May 1944.

It was followed by similar bubble-top variants, including the P-47D-26,

D-27, D-28 and D-30. Improvements added in this series included engine

refinements and the addition of dive recovery flaps. Cutting down the

rear fuselage to accommodate the bubble canopy produced yaw

instability, and the P-47D-40 introduced a vertical stabilizer

extension in the form of a fin running from the vertical stabilizer to

just behind the radio aerial. The fin fillet was often retrofitted in

the field to earlier P-47D bubble-top variants. The P-47D-40 also

featured provisions for 10 "zero length" launchers for 5 in (127 mm) High velocity aircraft rockets (HVARs), as well as the new K-14 computing gunfight. This was a license-built copy of the British Ferranti GGS Mark IID computing gyroscopic sight

which allowed the pilot to dial in target wingspan and range, and would

then move the gunfight reticle to compensate for the required

deflection.

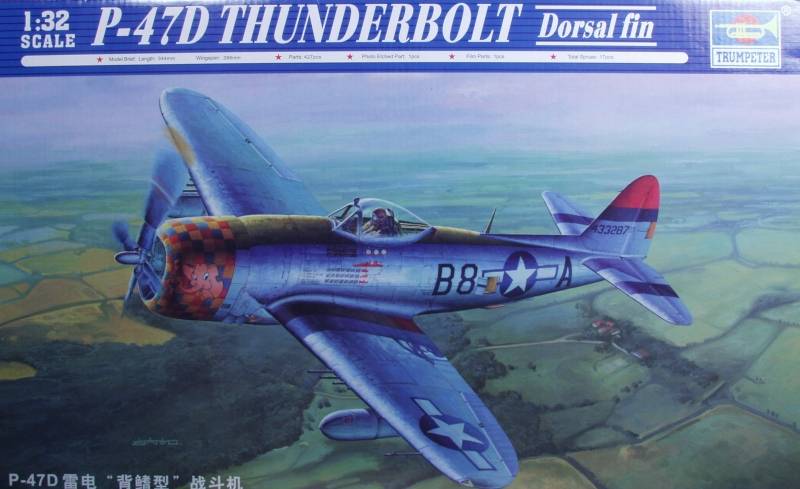

The Kit

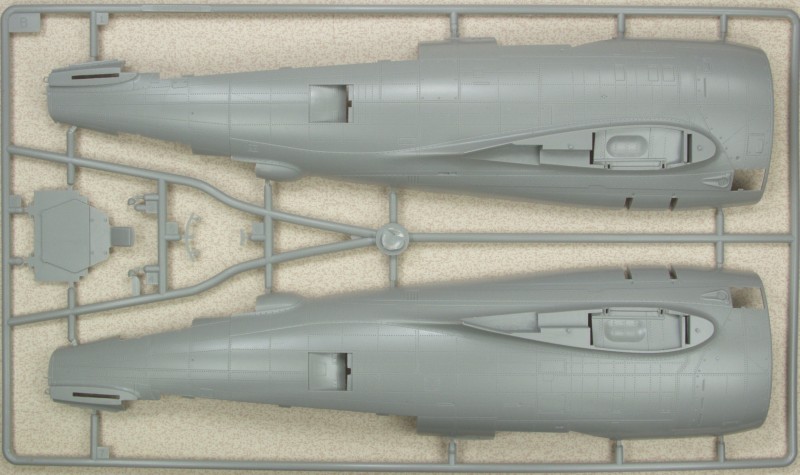

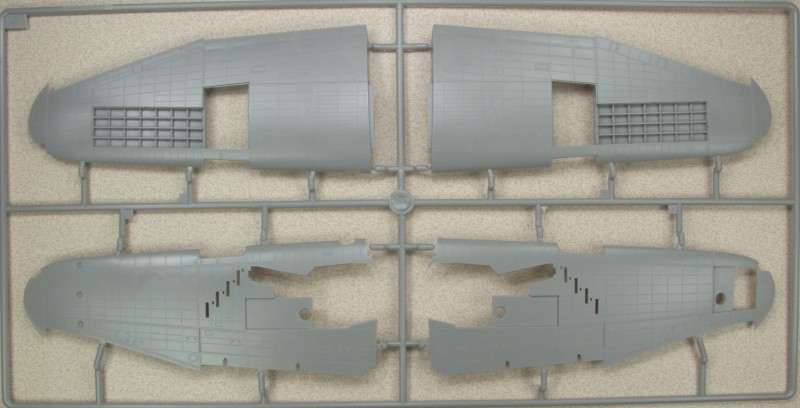

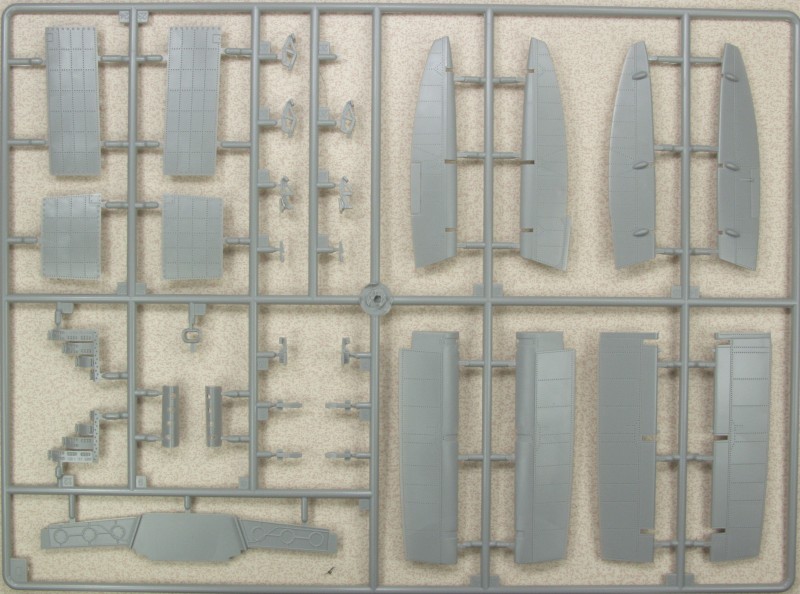

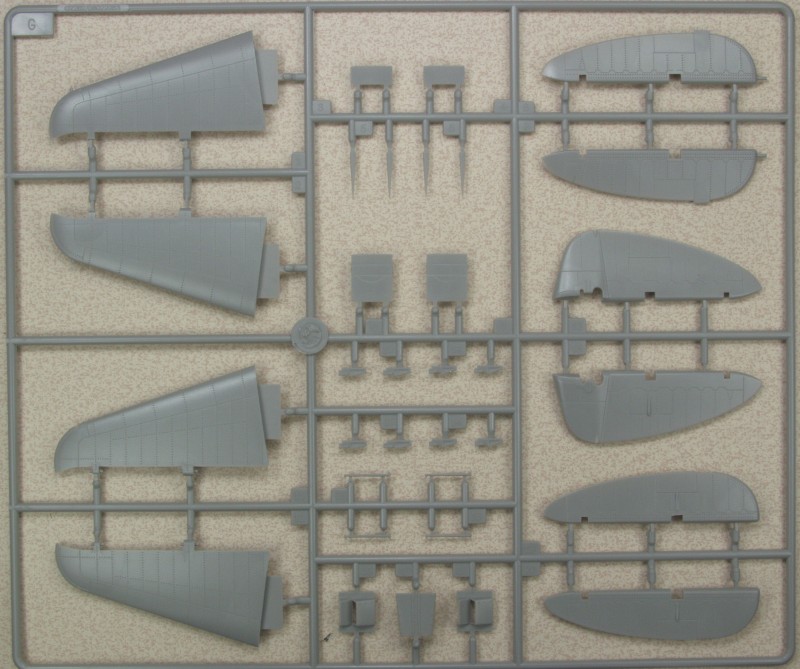

The Trumpeter kit comes in a large top open tray type box with the top made from heavy card stock and the bottom from thin corrugated cardboard. Inside the box the sprues are bagged either one or two to a bag. At one end of the box is a small box made of thin card stock that contains the clear parts, the vinyl parts and the photo etch fret. The parts are molded in a light gray color and feature recessed panel lines, rivets and fasteners. Some of the fasteners have slot detail. There is some raised detail where appropriate. The surface is glossy and the parts are crisply molded with only a hint of flash. The mold alignment looks good and mold parting lines are light. Looking over the airframe parts I did not find any obvious surface defects. As for ejector pin marks they seem to have been kept out of visible areas. The only ones that will be an issue are on the inside of the flaps if you chose to display them lowered.

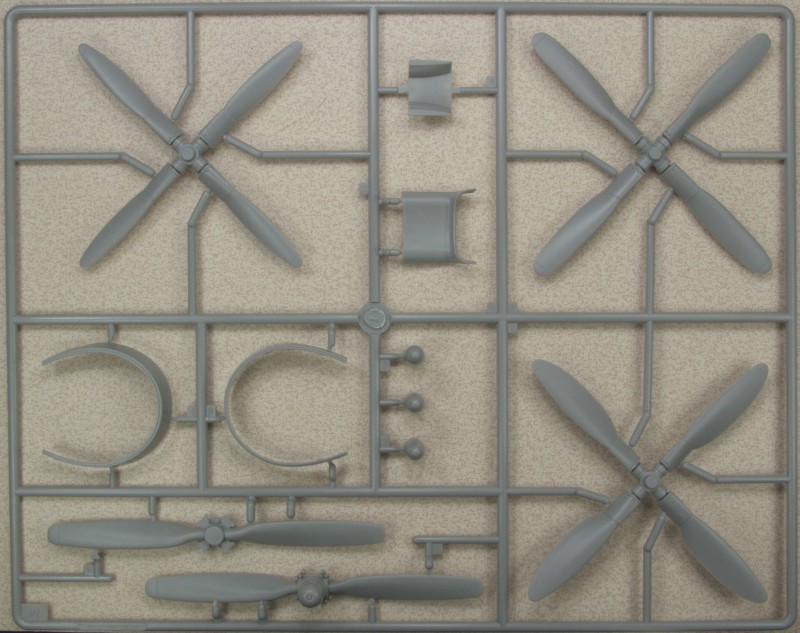

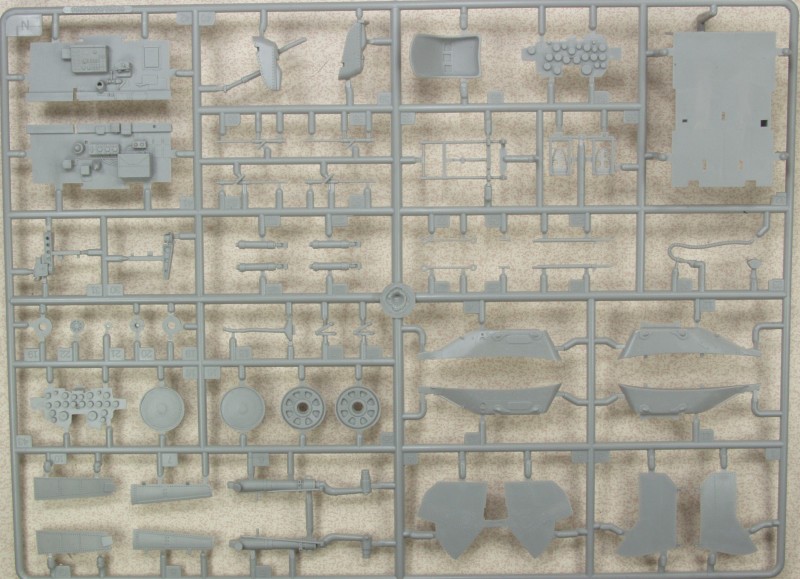

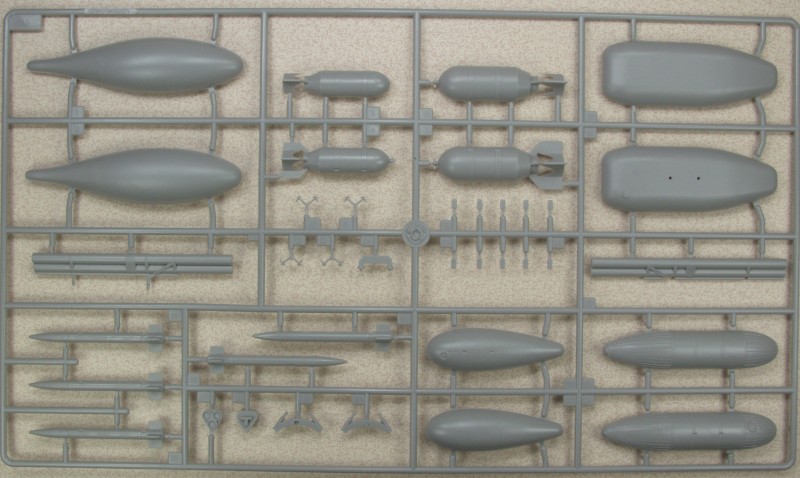

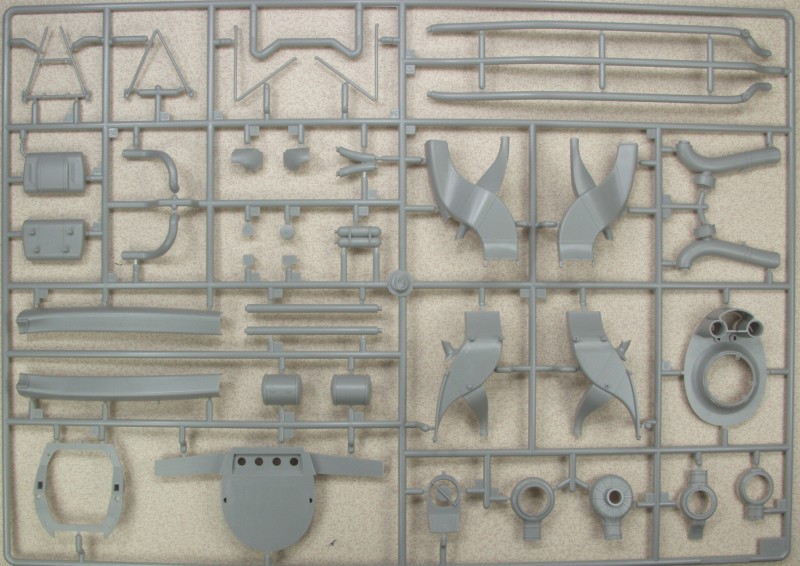

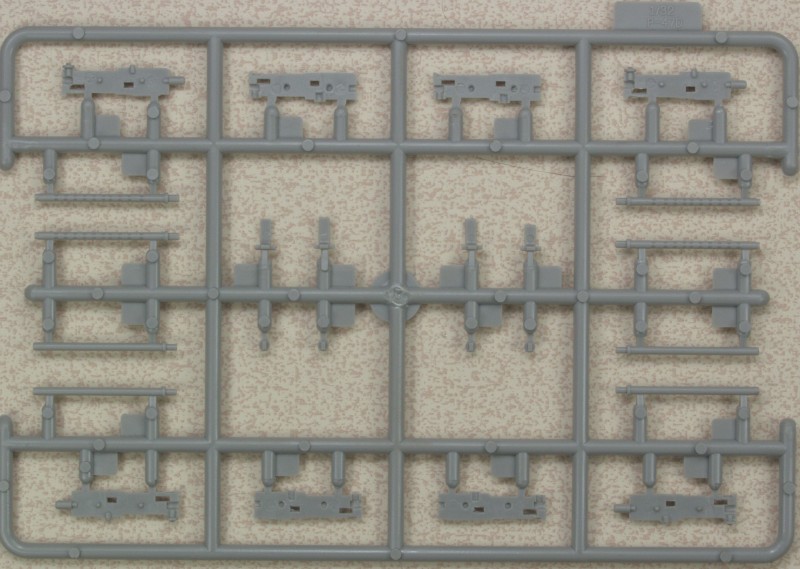

From a detail standpoint the cockpit looks a little light to me but much of the detail is molded on the side walls and it looks good, just needs some careful painting. The instrument panel has the typical clear front, film and back panel. The back panel has instrument body detail. Two different gun sights are supplied. From a nit pickers standpoint the floor is wrong for this version, it should be flat, not corrugated. The kit has Trumpeter's beautifully detailed engine needed only some plug wires to make it look complete and there is a nice clear cowling if you wish to show it off that way. Four different props are provided, three are one piece moldings the other molded in two pieces but know hint as to which one you should use for this version so a reference check will be needed. The contains the complete super charging system including all the duct work, which will never be seen once the kit is assembled. Some of it could be left out and none of it needs to be painted but part of it forms the inner sub structure to which the cockpit tub attaches. The engine accessory section is also detailed ahead of the cockpit firewall and again won't be seen after assembly. The control surfaces are all molded separately and the good news here is that they do not use the photo etch hinge system. The wings have detailed gun bays on the top side with separate panel. I have read that if you want these closed, for best fit one needs to add a shim to the mounting surface or they will sit some what recessed. Vinyl ammo belts are supplied. The lower wings have nicely detailed gear bays and the gear struts have molded on brake lines. The insides of the gear doors have nice detail as well. As for under wing stowage the kit includes two different styles of under wing drop tanks and two different types of belly mounted drop tanks. Note: Seven different auxiliary tanks were fitted to the Thunderbolt during its career. Also included are two 500 pound bombs, ten HVAR rockets and two three tube bazooka style rocket launchers. Lets look at the parts...

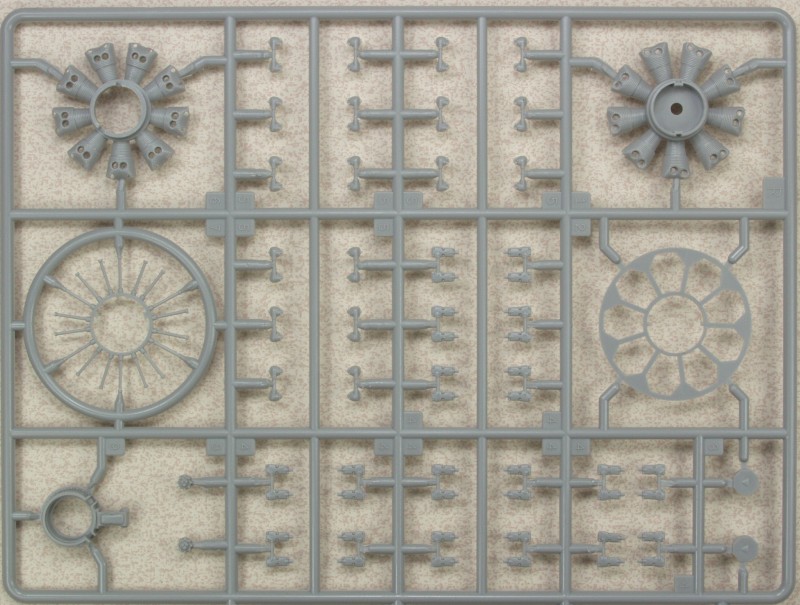

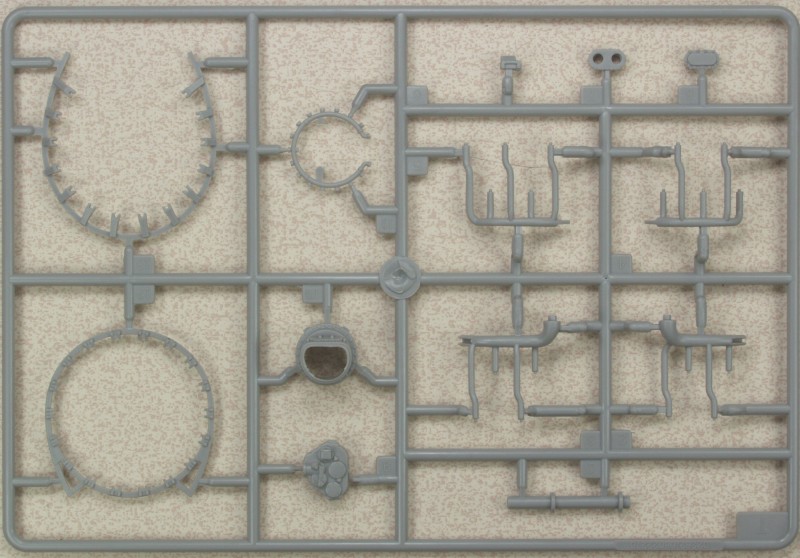

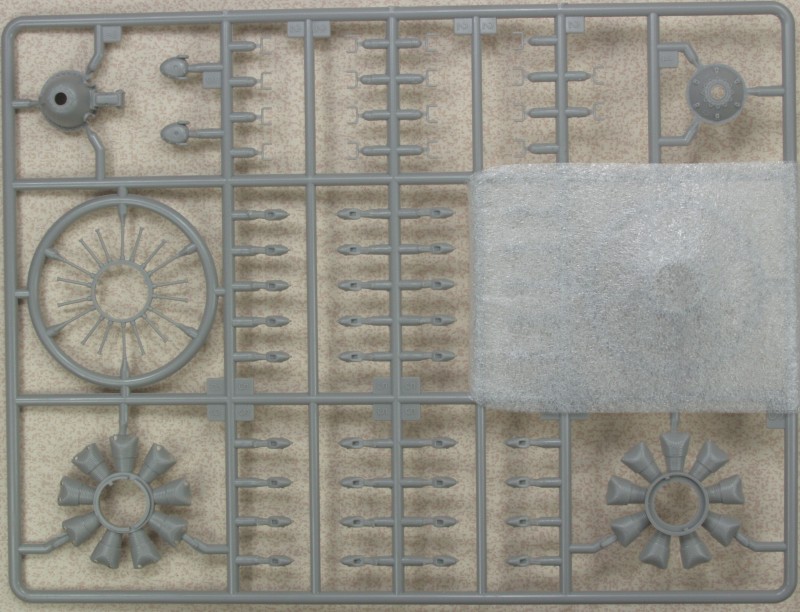

There are two of the following sprues.

There are two of the following sprues.

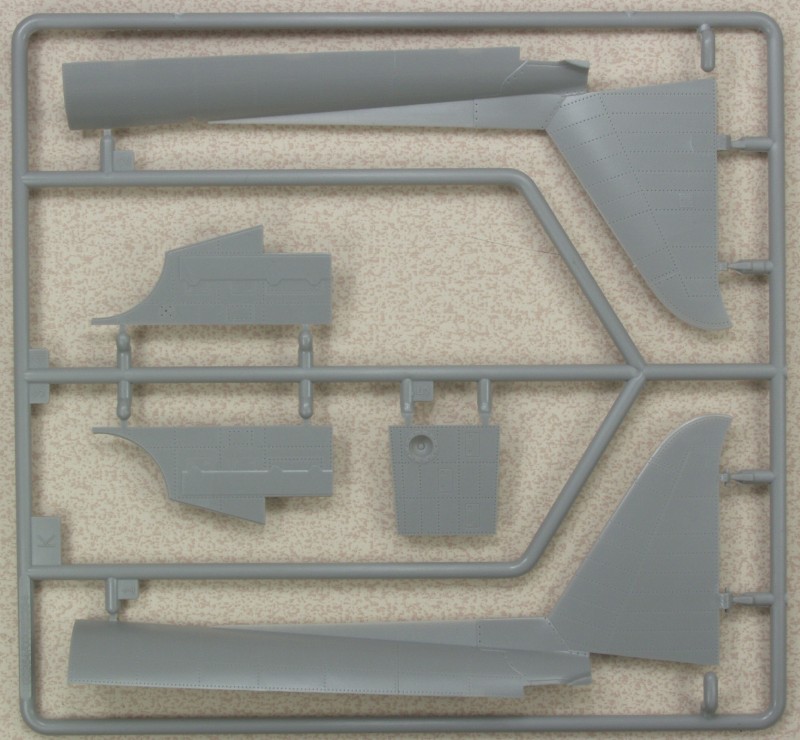

The part above that was protected by foam.

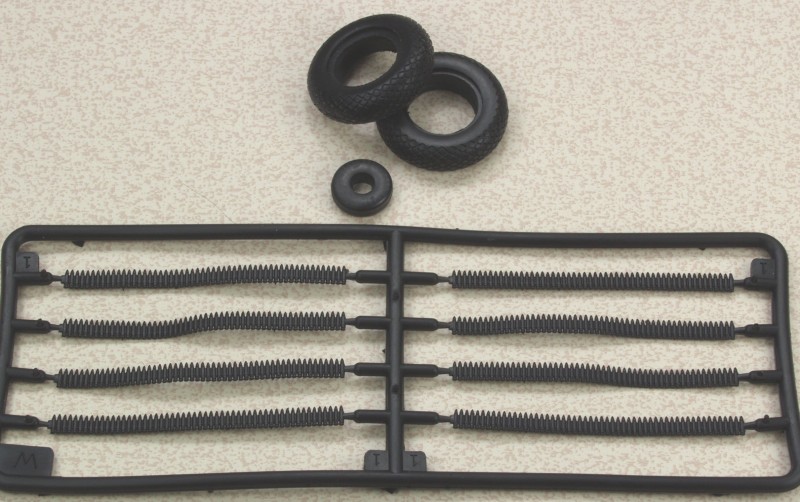

The vinyl tires and machine gun ammo belts.

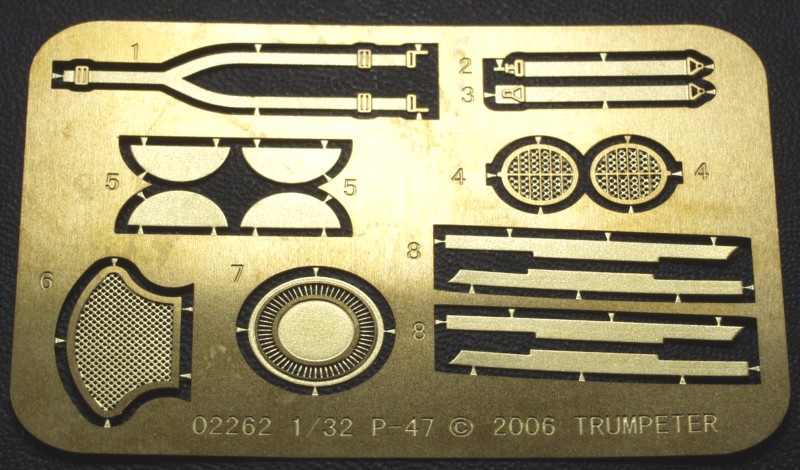

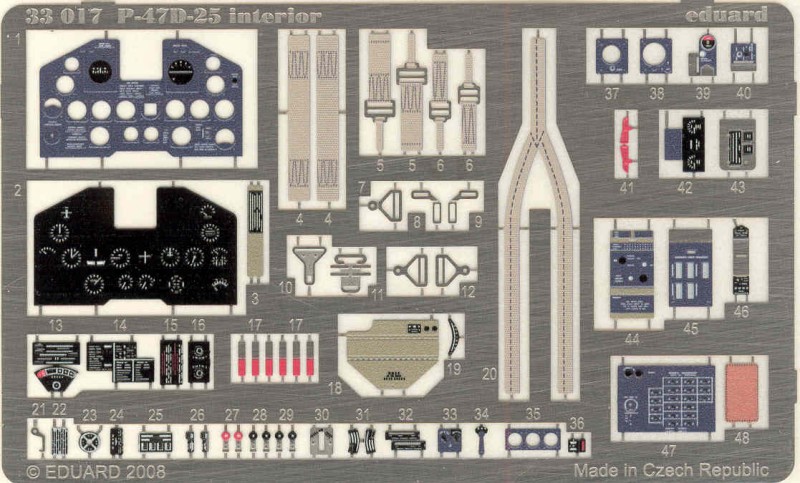

The photo etch fret with belts and harness, intake screens, turbocharger turbine and a couple other detail parts.

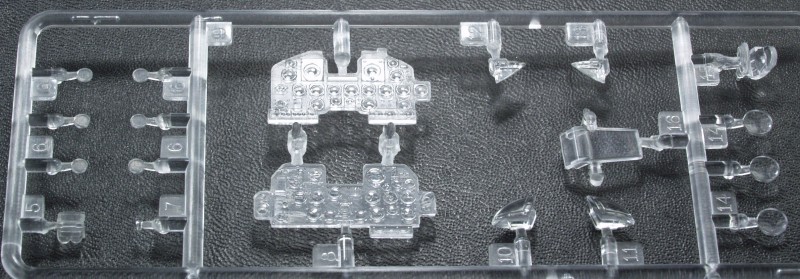

The clear parts are thin and nicely clear and the canopy can be posed open or closed.

The second sprue has the instrument panels and miscellaneous other clear parts.

And the clear cowling so you can see all of that lovely engine detail. This one is actually quite clear.

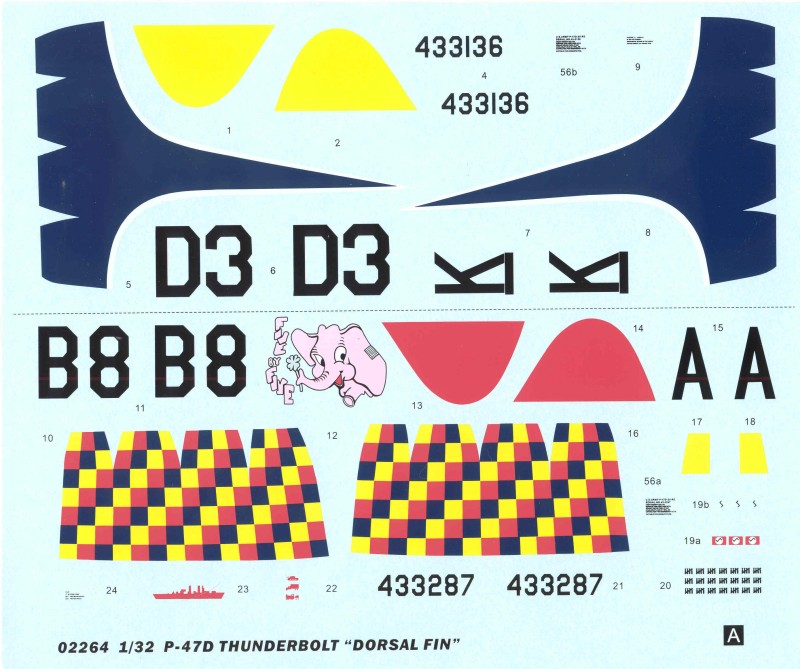

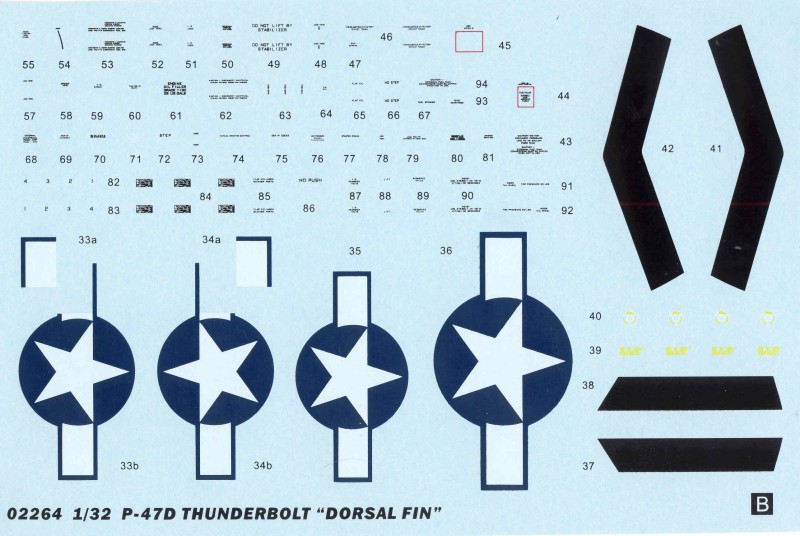

The decals are thin, appear to be opaque and in register. These are some large decals and I wonder how well they will fit. There are two large sheets, one with the individual aircraft markings and a second with the generic national markings and stencil data. A third small sheet has the girly decal, this comes in a black wrapper. The sheets provide markings for two aircraft; Col. Joe Laughlin. The Commanding Officer of the 362nd Fighter Group and Clifford Price's aircraft 397th and 368th Fighter Group. 9th air Force.

The instructions are a 16 page A4 sized booklet in the landscape format and stapled at the spine. The first page has general instructions and an icon chart, the next two pages are the parts map and the balance of the pages are the assembly diagrams in 31 steps. There are color call outs throughout the assemble referencing Gunze numbers. A separate page about 11 x 17" in size printed in color on glossy stock and has the painting and marking diagrams.

After Market Goodies

Not a lot is needed for this kit but I decided to replace the plastic gun barrels with some brass ones from Master Model (AM-32-004)

Another huge kit from Trumpeter. From all accounts it is quite build able and reasonably accurate. Thankfully they have dispensed with the annoying photo etch control surface hinges. Like most kits don't consider the painting instructions to be carved in stone, check references where possible. Because of it's complexity I would not recommend the kits to beginners but as long as yo pay attention to the instructions it shouldn't be difficult to all other. Recommended.

Links to kit build or reviews

A review/build can be found here

References

Famous Fighters of World War Two by William Green

Wikipedia

Back to the 1/32 U.S. Aircraft Page

Updated 3/18/17