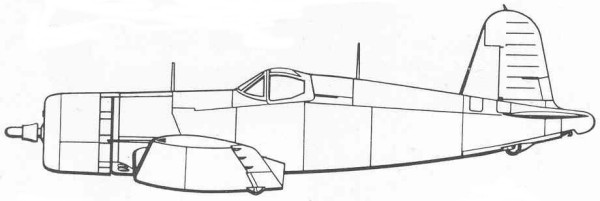

F4U-1

In June 1938, the U.S. Navy signed a contract with Vought for a prototype, the XF4U-1, BuNo 1443. After mock-up inspection in February 1939, construction of the XF4U-1 powered by an XR-2800-4 prototype of the Pratt & Whitney Double Wasp twin-row, 18-cylinder radial engine, rated at 1,805 hp went ahead quickly, as the very first airframe ever designed from the start to have a Double Wasp engine fitted for flight. When the prototype was completed it had the biggest and most powerful engine, largest propeller and probably the largest wing on any naval fighter to date. The first flight of the XF4U-1 was made on 29 May 1940. On 1 October 1940, the XF4U-1 became the first single-engine U.S. fighter to fly faster than 400 mph by setting an average ground speed of 405 miles per hour.

Formal U.S. Navy acceptance trials for the XF4U-1 began in February 1941. The Navy entered into a letter of intent on 3 March 1941, received Vought's production proposal on 2 April and awarded Vought a contract for 584 F4U-1 fighters, which were given the name "Corsair" on 30 June of the same year. The first production F4U-1 performed its initial flight a year later, on 24 June 1942. It was a remarkable achievement for Vought; compared to land-based counterparts, carrier aircraft are "overbuilt" and heavier, to withstand the extreme stress of deck landings.

The Corsair's aerodynamics were an advance over those of contemporary naval fighters. The F4U was the first U.S. Navy aircraft to feature landing gear that retracted into a fully enclosed wheel well. The landing gear oleo struts — each with their own strut door enclosing them when retracted — rotated through 90° during retraction, with the wheel atop the lower end of the strut when retracted; a pair of rectangular doors enclosed each wheel well, leaving a streamlined wing. The oil coolers were mounted in the heavily anhedraled center-section of the wings, alongside the supercharger air intakes, and used openings in the leading edges of the wings, rather than protruding scoops. The large fuselage panels were made of aluminum and were attached to the frames with the newly developed technique of spot welding, thus mostly eliminating the use of rivets. While employing this new technology, the Corsair was also the last American-produced fighter aircraft to feature fabric as the skinning for the top and bottom of each outer wing, aft of the main spar and armament bays, and for the ailerons, elevators and rudder. The elevators were also constructed from plywood. The Corsair, even with its streamlining and high speed abilities, could fly slowly enough for carrier landings with full flap deployment of 60°.

F4U-1: The first production version of the Corsair with the distinctive "bird cage" canopy and low seating position. The differences over the XF4U-1 were as follows: Six .50 in Browning AN/M2 machine guns were fitted in the outer wing panels, displacing fuel tanks. An enlarged 237 gal fuel tank was fitted ahead of the cockpit, in place of the fuselage armament. The cockpit was moved back by 32 in. The fuselage was lengthened by 1 ft 5 in. The more powerful R-2800-8 Double Wasp was fitted. 150 pounds of armor plate was fitted to the cockpit and a 1.5 in bullet-resistant glass screen was fitted behind the curved windscreen. IFF transponder equipment was fitted. Curved transparent panels were incorporated into the fuselage behind the pilot's headrest.The flaps were changed from deflector type to NACA slotted. The span of the ailerons was increased while that of the flaps was decreased. One 62 gal auxiliary fuel cell (not a self-sealing type) was installed in each wing leading edge, just outboard of the guns.

The Kit

This

kit I think has been reviewed in more places around the planet than any

other in memory and I doubt that there is anything I can add that would

contribute anything that has already been said about it. Until such

time as Tamiya moves the bar even higher this will remain one of the

best kits on the market today. In the reference section I have links to

what I think are probably the best reviews (best because they are

thorough and not presented by a shill and not because they gloss over

any issues).

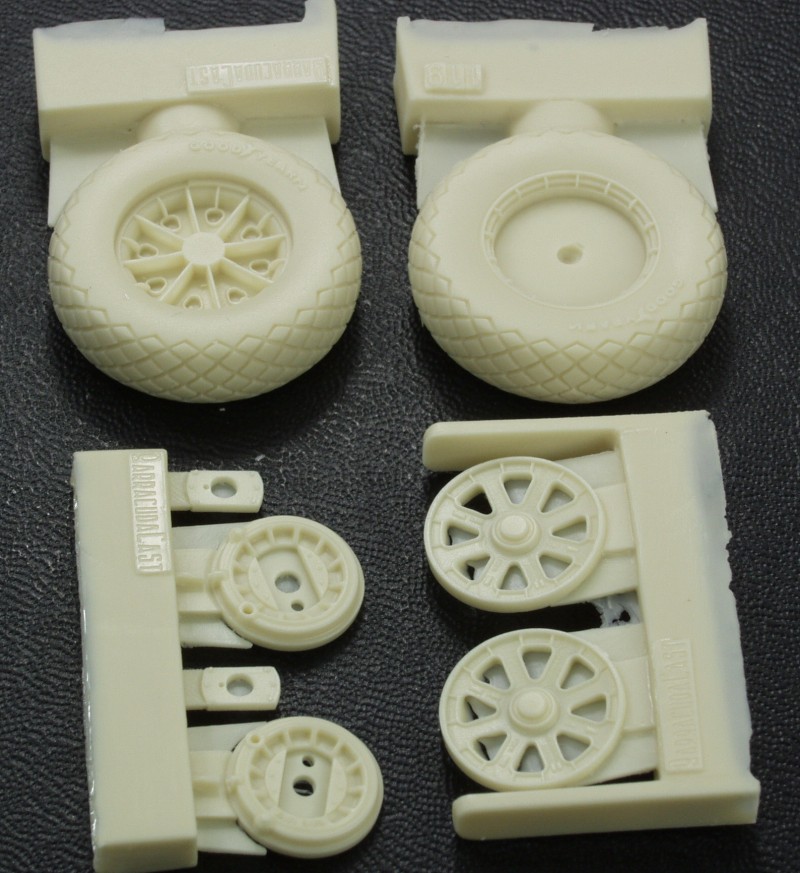

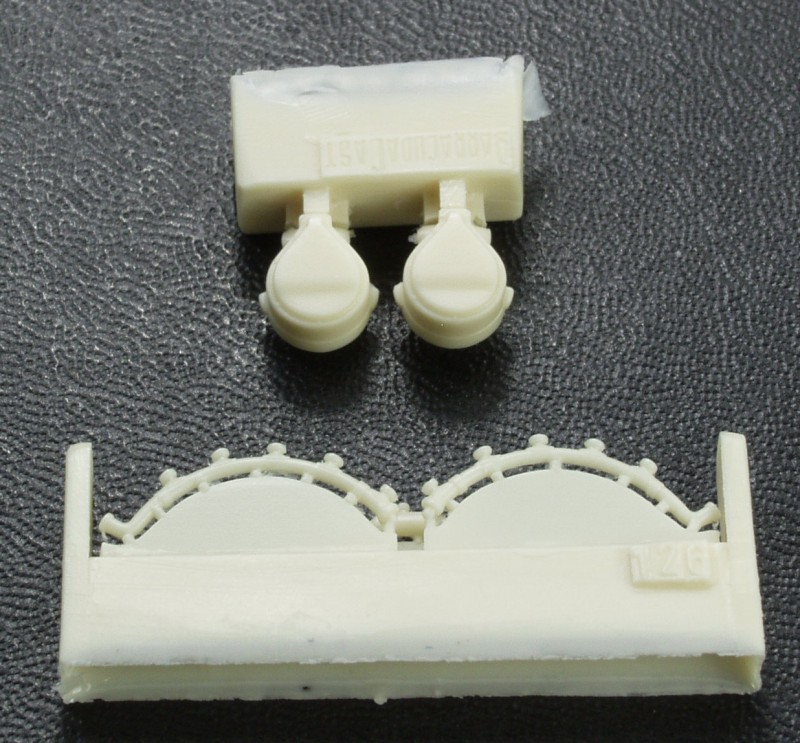

There is a plethora of after market for this kit although most of it relates to masking and decals as for the most part the kit parts are more than satisfactory. The most popular items seem to be resin replacement wheel sets since the kit supplies vinyl tires. The Corsair and Hellcat used the same wheels and tires so if you can't find specific Corsair wheels you can use the Hellcat wheels. Another up grade is one for the engine as the early F4U-1's used different magnetos and ignition harness than what is supplied with the kit. A wheel set (BR32119) and an engine set (BR32126) is available from Barracuda and are shown below. Barracuda Cast products are most excellent.

The only other item I have acquired are some fine mesh screens for the oil coolers from RB Productions (RB-P32035) and they are also shown below.

For what else might be available check you favorite online retailer or the list at Scalemates.

Conclusions

No need to pile on accolades, this is one of Tamiya's premo kits and every time I look at the box I want to dive into it. Due the the complexity of the kit I would discourage beginners from the kit but anyone with a few kits under their belts should be able to handle it if they take there time and do the radical thing of following the directions. Most heartily recommended.

Links to kit build or reviews

In box reviews can be found here, here, here.

A build review can be found here and as is usually the case no kit is perfect. This build review has a compilation of issues that the nit pickers of the world have compiled in case you are one of those that loses sleep at night over such issues.

References

History courtesy of Wikipedia

Back to the 1/32 U.S. Aircraft Page